Description

- Qualified in accordance with ICC-ES AC193 and ACI 355.2 for cracked and uncracked concrete for static, wind and seismic loading conditions

- Standard fractional sizes — the hole size matches the anchor size

- No special drill bit required — designed to install using standard-sized ANSI tolerance drill bits

- Removable — ideal for temporary anchoring or applications where fixtures may need to be moved

- Washer head allows screw anchor applications incompatible with a hex head

- For added convenience, a 1/2-in. socket adapter and (2) T-drive bits are included in each box

- Serrated teeth on the tip of the Titen HD screw anchor facilitate cutting and reduce installation torque

- Zinc plated; not recommended for permanent exterior use or highly corrosive environments

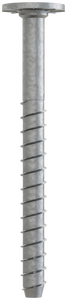

- Anchor size: 5/8 in. x 10 in.

- Quantity: 10

| Bit Size | 5/8" |

| Minimum Embedment | See PDF |

| Box Qty | 10 |

| Type | Male |

| Material | Carbon Steel |

| Environment | Dry |

| Minimum Spacing | See PDF |

| Minimum Edge Distance | See PDF |

| Maximum Fixture Thickness | See PDF |

| Minimum Fixture Hole Diameter (In Place) | See PDF |

| Minimum Fixture Hole Diameter (Hole Spotted) | See PDF |

| Maximum Torque | See PDF |

| Wrench Size For Nut | T60 6-Lobe |

| Brand Name | Simpson Strong-Tie |

The information on this page is intended for preliminary guidance only. For complete safety and to verify accurate information, please consult the (PDF linked below) to obtain the manufacturer’s values when selecting the anchors for your project.

The Titen HD with washer head is a high-strength screw anchor for use in cracked and uncracked concrete, as well as masonry. The washer-head design is commonly used where a minimal head profile is necessary. The model is offered in sizes suitable for use in sill plate applications, and the washer head's low installed profile means modular wall and floor systems can be installed on top with no need for notching the wall framing to accommodate the anchor. The anchor's 6-lobe drive eases driving and is less prone to stripping.

Installation

- Drill a hole in the base material using a carbide drill bit the same diameter as the nominal diameter of the anchor to be installed. Drill the hole to the specified embedment depth plus minimum hole depth overdrill (see table below) to allow the thread tapping dust to settle, and blow it clean using compressed air. (Overhead installations need not be blown clean.) Alternatively, drill the hole deep enough to accommodate embedment depth and the dust from drilling and tapping.

- Insert the anchor through the fixture and into the hole.

- Tighten the anchor into the base material until the washer head contacts the fixture.

| Titen HD Diameter (in.) | Drive Type | Recommended Fixture Hole Size (in.) | Min. Hole Depth Overdrill (in.) |

|---|---|---|---|

| 1/2 | T50 | 3/4 to 11/16 | 1/2 |

| 5/8 | T60 | 15/16 to 13/16 | 1/2 |

Caution

- Holes in metal fixtures to be mounted should match the diameter specified in the table above.

- Use a Titen HD screw anchor one time only — installing the anchor multiple times may result in excessive thread wear and reduce load capacity.

- Do not use impact wrenches to install into hollow CMU.

- Oversized holes in base material will reduce or eliminate the mechanical interlock of the threads with the base material and reduce the anchor’s load capacity.

- Installation of concrete screw generally is influenced by many factors such as but not limited to, concrete compressive strength, type of aggregate, installation location, installation direction and tools used for installation.

![]() Product Information (on Simpson Website)

Product Information (on Simpson Website)

Package information

12.625 in. x 3.54 in. x 3.54 in., 9.3 lbs.

California Prop 65 WARNING! Cancer -www.P65Warnings.ca.gov

Carton Reference 10707392014895

Pallet Reference 50707392014893